Right-Sized Cereal Box Designing Dimensions That Protect, Promote, and Sell

Date: 23-09-2025 | Read Time: 7 Mins

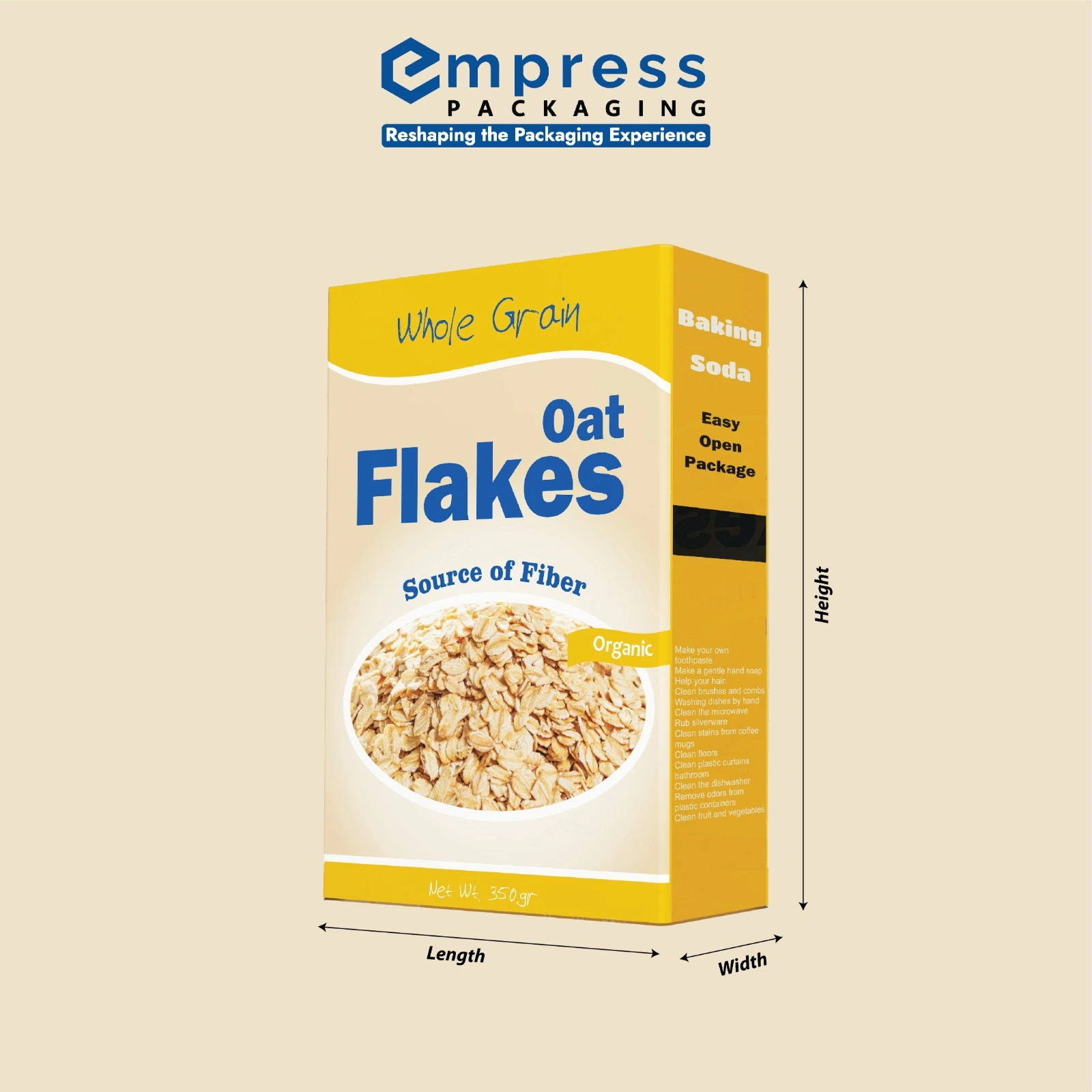

The right cereal box size is a researched choice that will take into account customer use, shelf presence, product protection, and delivery economics. Fill volume, packaging, headroom for toppings or fragility, and the variety of visual areas available for branding and nutritional information are all impacted by box size. Small custom boxes can break flakes or restrict printed storytelling, while oversized boxes will increase shipping expenses and shelf waste. To make the box a useful carrier and a marketing surface, start by deciding on your SKU strategy (single-serve, family, bulk, or multipack). Then, use that information to guide dielines, board grades, and within supports.

Standard Sizes, Formats, and How to Choose?

Rectangular boxes are commonly used in custom cereal boxes in a variety of standard designs to include multi-pack shippers, regular family-size (medium), large bulk or value (large), and simple-serve sleeves (small). Although precise measurements vary based on fill weight and product density, typical family-size dimensions. Determine the size by considering the product`s bulk density (flakes vs. clusters), the number of grams or ounces per box, and whether inner bags are included. To make sure your selected custom boxes will satisfy merchandising requirements, take into account retailer planogram restrictions, standard gondola increments, and also shelf depth.

Structural Considerations and Internal Protection

Custom Boxes should be designed to avoid shifting, crushing, and moisture entry. For large groups or delicate parts, use corrugated liners, bent trays, or internal gussets to maintain shape. To avoid top crushing when stacked, include a small headroom and a sturdy board or inner tray for products with tiny toppings or groups. Use crash-lock or tuck-top lock bottom design for stability and packing speed. Select corrugated boxes from Empress Packaging that are the right size to reduce empty space when shipping in master boxes, and use fill or barriers to support inner units to prevent movement on shelves.

Material Choices and Sustainability Trade-offs

Print quality and durability are both affected by board grade. Kraft boxes have an eco-friendly look and are frequently composed of recycled fibers; custom cardboard boxes with an extra caliper offer will clear graphics and respectable strength. Long shipping and wholesale will require corrugated boxes. Choose water-based inks, FSC certification, and recycled content board for eco-friendly solutions. Take into account: glossy laminates may restrict recyclability, whereas most coatings maintain it. Onboard GSM, flute size for corrugated shippers, and coatings that will strike a balance between aesthetics and recyclability are all things your custom box manufacturer should advise.

Shelf Impact, Display and Retail Constraints

Planning efficiency and sides are important to retailers. Select custom printed box widths and heights in order to maximize the face area while staying within the shelves. Wider, low-profile boxes will improve shelf density, whereas tall, thin boxes provide a strong vertical appearance. Create boxes that lay on trays that are ready to be placed on shelves for in-store displays, or turn master boxes into temporary displays for special offers. To encourage impulsive purchases, think about using sample or single-serve packaging that are the right size for checkout areas. To avoid eliminations and ensure a simple in-store deployment, confirm your chosen measurements against the shipping and display requirements of the retailer.

E‑commerce, Fulfillment, and Dimensional Weight

Direct-to-consumer cereal sales have to be economical and able to withstand transport. Custom packaging boxes of the proper size will reduce dimensional weight charges; use boxed multipacks or tight inner bags to prevent too much empty space. To avoid crushing during transit, corrugated outer shippers should have partitions and fit inner units tightly. Flat-pack dielines will speed up assembly for subscription or direct-to-consumer fulfillment by reducing the bulk of warehouse storage. To lower returns and shipping expenses, test common pack combos to determine the ideal balance between a retail custom box that will face customers and ship-ready inside packaging.

Testing, Prototyping, and Supplier Collaboration

To verify fitting with the actual cereal volume and inside bag performance, build dielines at full scale. To make sure the custom printed cereal box holds up against warehouse packing and seasonal variations in humidity, do drop, compression, and moistures tests. Consult a custom box manufacturer that will provide materials guidance, quick testing, and prototyping. Check the movement composition of glue points, closure strength, and printing registration in automated packing cases. In order to balance cost, protection, and brand impact,continuous elevating testing minimizes damage claims which improves material selection, and also enables you to fine-tune measurements.

Cost, Scale, and Wholesale Logistics

Consider the number of orders while making tooling and print decisions. For limited seasonal or test-market SKUs, digital printing will lower minimums; offset lowers cost per unit at scale. Cut freight and unit expenses for retail shipments by using packaging boxes wholesale deals for corrugated boxes. In order to prevent stockouts and align promotional cycles, negotiate MOQs, lead times, and warehousing. When choosing dimensions, take into account the entire landed cost, including board quality, printing finishes, inner bags, and shipping, to make sure price positioning aligns with profit margins and store pricing expectations.

Consumer Experience and Practical Usability

Cereal packaging should be easy to open, reseal, and pour. look for removable flaps, pour spouts, or inner zippers when appropriate. Ensure the within bag material is food-safe and also preserves crispness; custom package design should allow consumers to access and reseal with no mess. Clear instructions or visible windows can also improve shopper confidence. A custom box that will store neatly in pantry spaces, stacks well, and pours cleanly also improves repeat purchase rates and customer overall satisfaction.

Conclusion:

When cereal box sizes are optimized for fill density, retail diagrams, and shipping economics, you will minimize damage and shipping penalties while improving shelf impact and ease for consumers. This will tie together product protection, brand storytelling, cost control, as well as sustainability. Work with a reputable custom box manufacturer to design and evaluate dielines, board grades, and inserts to verify performance by using compression and drop tests; and weigh print and finish choices against recyclability objectives. Analyze custom package size as a strategic choice that will boost ongoing brand growth, increase profitability, and also improve the opening experience.

Request a Quote

Related Blogs

Published on 28-10-2025 Premium Custom CBD Boxes for Retail Success

Published on 20-10-2025 How Many Packaging Boxes Are Delivered Each Day in the U.S.?

Published on 20-10-2025 Packaging Perfected: Your Guide to Mailer and Shipping Boxes

Published on 13-10-2025 What is Smart Packaging Boxes?

Published on 08-10-2025